Corrective Action Response: Sources – Part 1 of 2

Skip to Part 2 of Corrective Action Responses addresses Planning and Closure

Sources of Corrective Action Requests

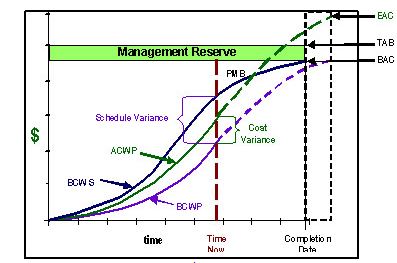

A healthy part of any system, including an Earned Value Management System (EVMS), is regular review and surveillance by both those who operate within the system (the contractor) and those customers who rely on information from the system to manage programs. The DCMA and the DCAA have the responsibility to conduct surveillance for all Department of Defense (DoD) contract efforts that require Earned Value regardless of whether a validated system is required. Similar guidelines exist for those agencies that do not use the DCMA for surveillance, such as the Department of Energy.

A healthy part of any system, including an Earned Value Management System (EVMS), is regular review and surveillance by both those who operate within the system (the contractor) and those customers who rely on information from the system to manage programs. The DCMA and the DCAA have the responsibility to conduct surveillance for all Department of Defense (DoD) contract efforts that require Earned Value regardless of whether a validated system is required. Similar guidelines exist for those agencies that do not use the DCMA for surveillance, such as the Department of Energy.

In addition, other reviews such as an Integrated Baseline Review (IBR) or technical program reviews are also conducted during the life cycle of most programs. Normal results of system surveillance and program reviews are findings or issues discovered during the review. The findings are usually documented in Corrective Action Requests (CARs) and Discrepancy Reports (DRs). Often, the DR form is used to identify the finding, which is delivered to the contractor in the CAR form.

The current guidance used by the DCMA for conducting surveillance is the Standard Surveillance Instruction (SSI), which can be found on the DCMA Guidebook. In addition to system surveillance, the DCMA EVM Center conducts Compliance or Validation reviews that may result in corrective actions required by the contractor. Currently the DCMA is evolving its approach to the compliance evaluation of DoD contractor systems. Because of a desire to standardize across its reviewing organizations and the reduction in resources available to conduct on-site reviews, the DCMA is transitioning to establishing predefined success criteria and testing methods to evaluate the compliance of each guideline using data submitted by the contractor.

This does not change the components of a compliant EVMS; it merely adjusts the priority of the review steps required for a compliance rating. Regardless of the method, a complete EVMS should consist of:

- A set of procedures that are compliant with the EIA-748 Guidelines and followed by the contractor organization;

- System output, or data, that is valid, reliable, and auditable. This data will have demonstrable integrity and compliance to EVM requirements;

- A disciplined work force that uses the EVMS to manage programs and accurately inform the customers of current status, future conditions, and management decisions.

Discrepancy Reports are documented whenever issues are discovered during the system review that involve non-compliance with contract requirements, including the EIA-748 and the Data Item Descriptions (DID) for the Contract Performance Report (CPR) or the Integrated Project Management Report (IPMR), or the Integrated Master Schedule (IMS). The finding is documented in a Discrepancy Report (DR), which identifies the EVM Process Group (Organizing, Scheduling, Accounting, etc.) and the specific guideline regarding the finding. Additional information might include the source of the issue such as the CAM name, Control Account title, or the process document that was reviewed. The DR may also include attachments or exhibits which provide examples of the discrepancies.

The DCMA, or the DCAA, may choose to communicate the DRs in the form of a CAR. The severity of the findings determines the level of the CAR issued:

- Level 1: For more minor issues that require no special management attention to correct. Usually directed to the working level personnel of the contractor.

- Level II: For non-compliance that is systemic in nature and could adversely impact cost, schedule, or performance if not corrected. A Level II CAR may be the result of Level I issues that are found across several programs or involve several CAMs. They are issued to the contractor’s management level responsible for the process with a copy to the Administrative Contracting Officer (ACO).

- Level III: For non-compliance where cost, schedule, technical performance, resources, or management process issues have unfavorably affected program performance and have not been corrected. These may also be issued when the Corrective Action Plans associated with Level II CARs have been unsuccessful. In addition, noncompliance with any of the sixteen foundational guidelines will immediately be classified as a Level III CAR. Level III CARs are issued to the contractor’s top tier business manager at the site where the discrepancies were noted. This CAR level may trigger other reviews such as a review for cause or a compliance review, which could result in a suspension of the contractor’s EVMS validation.

- Level IV: Generally results from an escalation of a Level III CAR, but issued to the contractor’s corporate level. They are often used to advise the contractor of contractual penalties; such as payment withholds, termination for default, suspension, etc.

Both Level III and IV CARs may result in a “business system” withhold. DFARs 252.242-7005* identifies 6 business systems that may result in payment withholds if significant deficiencies are found, these are: Accounting, Earned Value Management, Cost Estimating, Material Management and Accounting, Property Management, and Purchasing. Deficiencies found in a single business system may result in up to a 5% withhold; however, if there are multiple business systems cited for deficiencies the withholds may be as much as 10%.

At this point, the submittal of a quality and timely Corrective Action Plan (CAP), and following through with implementation of the actions is critical. If the contractor submits an acceptable CAP within 45 days of the Contracting Officer’s (CO) intent to withhold payments, and the CO believes the contractor is implementing the plan, the withholds may be reduced to 2%. However, if at any time the CO determines that the contractor is not following through on the corrective actions, the payments may be increased to 5%.

When the CO determines that corrective actions are implemented and are expected to correct the significant deficiencies, the CO will discontinue withholding payments and release any payments previously withheld. Previously withheld payments are not released when the withhold is reduced from 5% to 2%; only when the corrective actions are proven to correct the findings.

In part 2 of Corrective Action Response, we will address Planning and Closure.

*Resource blog – DFARS 252.234-7001 – “Thou Shalt Do Earned Value”

Corrective Action Response: Sources – Part 1 of 2 Read Post »