Part 3: IMS Health Problems; Data Item Non-Compliance; Planning Package Misuse

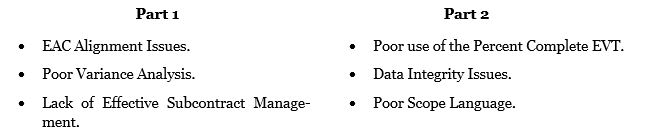

This is the third part of a five part series regarding common findings discovered in Earned Value Management Systems (EVMS) reviews and the recommended corrective actions to help mitigate those findings. The previous two articles discussed:

The topics anticipated for parts four and five are:

Part 4: Misalignment between BCWP and ACWP; Freeze Period Violations; Failed Data Traces.

Part 5: Inappropriate use of PERT and LOE; Misuse of Management Reserve; Administrative CAMs.

1. IMS Health Problems

Several years ago the Defense Contract Management Agency (DCMA) issued the 14-Point Assessment Metrics. Twelve of the metrics are related to the “health” of the Integrated Master Schedule (IMS) while the remaining two (critical path length index and baseline execution index) are “tripwire” metrics for schedule performance. Of the 12 health metrics, H&A has found that most discrepancy reports (DRs) are associated with missing logic, high total float, and high duration.

Missing Logic: The DCMA uses logic checks to identify any incomplete tasks that are missing a successor or predecessor, or both. As a rule of thumb, all activities should be tied to at least one predecessor and one successor with the exception of the first and last activities (respectively) in the project. By the DCMA’s standards, there is an allowance of 5% for activities not having these types of relationships; but some believe that may be too loose. In the Planning and Scheduling Excellence Guide or PASEG (National Defense Industrial Association, June 2012, version 2.0) states that all discrete tasks (excluding receipts/deliveries, LOE and summary tasks) should have at least one predecessor and one successor as even one missing logical tie could adversely affect the program’s ability to successfully execute the contract.

High Total Float: Total float (or “total slack” for Microsoft Project users) is the amount of time an activity can be delayed or expanded before the finish date of the project is affected. In the DCMA Program Analysis Pamphlet (DCMA-EA PAM 200.1, April 2012), any incomplete tasks with total float greater than 44 working days are considered as having high total float; an allowance of 5% is also given before this metric trips a red flag. The primary drivers for inappropriate high total float are missing successor linkages or planning well in advance of need. For this metric, however, there are many conditions that may drive a high total float value that are perfectly legitimate. This is especially true for longer projects and production projects that often receive materials well advance of need.

High Duration: The DCMA Program Analysis Pamphlet classifies incomplete activities with a baseline duration greater than 44 working days as having “high duration”, and again have applied a 5% threshold to the metric. The fear of very long tasks is that they may not provide enough precision for measurement of accomplishment and will introduce subjectivity into the statusing process. As with total float, there may be conditions that drive high duration activities that are justifiable. This is often the case when activities are representative of schedules outside of the IMS, such as at subcontractors or manufacturing planning systems.

Most Common Corrective Action Plans

The IMS is a critical management tool, and the purpose of the health metrics is to ensure that it provides an accurate plan and reliable forecasting for program management and execution. The basic approach to resolving DRs written for IMS health issues is to first take all the necessary steps to improve the real health of the schedule using the metrics as indicators. This includes a thorough review of the linkages, relationships, and task durations on an ongoing basis. Organizations should establish a health check “rhythm”, to be used to review the IMS prior to customer submittal. This process should also require the CAMs and their scheduling support staff to justify any conditions that may drive tripping a metric.

The contractor should work with its customer to gain a mutual understanding of the conditions that may legitimately result in high total float and high duration activities. Contractors should try to avoid taking illogical actions, such as adding unnecessary linkages or arbitrarily breaking tasks into small durations simply to meet the metric requirements. The IMS health metrics are simply indicators of potential issues. If the nature of the program were one where relatively higher total float values or high durations are to be expected, the appropriate thresholds for tripping a metric may be higher than the standard 44 days. In these cases, it is worth having a discussion with the customer to establish new metric thresholds.

2. Data Item Noncompliance

The reports that are generated from an EVMS or IMS, and delivered to the customer, are usually placed on the contract by the incorporation of a Data Item Description (DID) and included in the Contract Data Requirements List (CDRL). As of June, 2012, both earned value and schedule reporting are included in the Integrated Program Management Report (IPMR), DI-MGMT-81861. It is important to generate the system reports in accordance with the appropriate DID as the requirements have changed with progressive releases.

Prior to the IPMR DID, IMS reporting was required per DI-MGMT-81650. For EVM reporting, the previous DID was DI-MGMT-81466A, Contract Performance Report (for contracts established between March, 2005 and June, 2012), and before that was DI-MGMT-81466 or the Cost Performance Report. The release of the Contract Performance Report DID in March 2005 also eliminated the use of the Cost/Schedule Status Report (C/SSR, DI-MGMT-81467) for new contracts. There are, however, active contracts which use any one of the above DIDs as the requirements document for earned value and schedule reporting, and compliance of the submitted reports is evaluated against the DID that is required on each contract.

Data Item Descriptions are not just guidelines for reporting, they stipulate the contractual requirements for the documents. There are 203 uses of the word “shall” in the current IPMR DID, and some of these “shall statements” refer to a list of many requirements. Any planned deviation, or tailoring, from the DID must be approved by the Procuring Authority and documented in the CDRL (DD 1423-1 on DoD contracts). Section 3.0 of the “IPMR Implementation Guide” (OUSD AT&L PARCA, January 24, 2013) provides tailoring guidance for the IPMR.

Software programs used to generate the IPMR formats have reduced the amount of data specific errors in the reports; however, there are many requirements in the IPMR that are not related to data reporting. In the requirements for the Format 5 (Explanations and Problem Analyses), for example, there are nine discussion requirements in addition to the required explanations for cost and schedule variances that exceed the variance thresholds. The narrative portions of the IPMR cannot be generated by a software tool.

A contributing factor in the delivery of poor data items is when the customer encourages noncompliance or does not provide feedback on submitted reports. It is easy to fall into apathy regarding compliance to the DID when there is no motivation to do so. This situation, however, does little to convince other reviewers, such as the DCMA, that noncompliance is allowable.

Most Common Corrective Action Plans

When DID noncompliance is found and communicated to the contractor, the best immediate approach is correction and resubmittal of the document. Noncompliance is most likely a discipline issue which requires a structured approach to developing the report, training the personnel who are responsible, and a thorough review prior to submittal. Many organizations develop checklists that are used to ensure that all the requirements have been met prior to submittal. There are also training materials available which can provide cell-by-cell instructions to make the proper entries into these reports (H&A has a DVD titled “Contract Performance and Funds Status Reports (CPR/CFSR) Completion and Reconciliation”). It may be worthwhile to develop a “buddy system” with another program or another part of the company to exchange outside review and evaluation of data items. This type of accountability can be mutually beneficial.

3. Planning Package Mismanagement

A planning package is far-term effort in a control account that cannot yet be subdivided into detailed work packages. Planning packages share similar attributes as work packages, such as a time phased budget, a scope of work, start and finish dates, and must have enough detail in the IMS to support the development of a critical path. There can be no accomplishment or actual costs recorded against the scope and budget that is defined in a planning package. When enough information is available to detail plan the planning packages, they are converted to work packages. This is done through a process called “Rolling Wave Planning”, and it is a good practice to have the detailed information available for at least six months in advance. Advanced detailed planning is an effective approach to avoid unpleasant surprises, such as lack of availability of the necessary resources or the necessity to begin a hiring exercise. In addition, near term lack of detail in the Integrated Master Schedule may drive improper or incomplete logic ties, which will impact total float and critical path analyses.

Company EVMS System Description Documents (SDDs) should provide guidance for rolling wave planning, including rules for any baseline adjustment in the current or near term periods. It is important that planning packages are not allowed to exist in the current or past periods. It is also improper for any actual costs (ACWP) or performance (BCWP) to be recorded against a planning package. Most earned value engine software tools prohibit this, but some contractors have been known to override that prohibition in the toolset. In addition to ACWP and BCWP, there should also be no cumulative BCWS in the current period for any planning package. Cumulative BCWS is the most noticeable evidence that a planning package was not converted to a work package in a timely manner.

Most Common Corrective Action Plans

The most common corrective action is to conduct a monthly analysis of the EVM data to identify planning packages that are nearing the planning period. While it is the responsibility of the control account manager (CAMs) to convert planning packages to work packages, Project Controls can easily provide the CAMs with a list of planning packages needing conversion. If there is no guidance or process written for rolling wave planning, these should be developed to provide instructions to the CAMs and the support staff. It is also critical that organizations maintain the restrictions in the earned value engines to prohibit the accrual of earned value or actual costs for planning packages.

Please contact Humphreys & Associates if you have any questions on this article.

Pingback: Common Problems Found in EVM Systems & Recommended Corrective Actions

Pingback: Common Problems Found in EVMS & Recommended CAs – Part 5