EVM Lite – Part 2: Tailoring approaches to EV Lite

So, what if there is no EVMS contract requirement, but a company wants to use the EVM principles to measure performance on important work?

Approaches for tailoring EVM Lite (also called EV Lite):

- First, the levels of the Work Breakdown Structure (WBS) could be limited to minimal extension. With fewer lowest level WBS elements, fewer control accounts are created which results in a reduction in the overall administrative costs of the system.

- Similarly, responsibility can be assigned to managers higher in the Organization Breakdown Structure (OBS), or Integrated Product Teams can be used to combine functions. By having fewer lowest level OBS elements, fewer control accounts will be created. Most contractors are well aware of these implementation tactics and actively engage in them.

- Other approaches include the Project Schedule – more distance between the milestones and use of the Percent Complete Technique, providing the validity of the Earned Value (EV) data is unaffected. Also, the Variance Analysis Report Thresholds could be tailored to specific risk areas and made less stringent. The Change Control Process could be tailored to a more streamlined transfer of work and budget involving Stop Work Orders.

- With respect to reporting, The Integrated Program Management Report (IPMR) or Contract Performance Report (CPR), Format 2, Organizational Categories, and Format 4, Staffing, could be eliminated.

- In some cases, Format 3, Baseline is eliminated. Note: The new IPMR Guidance does not allow tailoring of the Contract Data Requirements Item List (CDRL) to removed reports on contracts that exceed $50 million. None of the bulleted “EVM Lite” items above are even in the realm of the acceptable items for EVMS tailoring. If a company has an EVMS contract requirement, EVM Lite will not receive a favorable reaction from the DCMA.

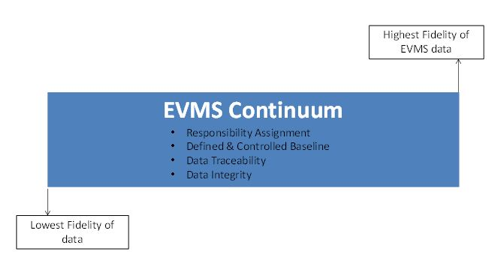

Some companies use EVM for critical internal Research and Development projects or fixed priced work. Companies need to ask the question “Where do we want to fit in the EVMS Continuum?” Consider the graphic below:

The right hand side of the continuum represents implementation of EVMS to the maximum, and represents the highest cost to operate and maintain an EVMS. The left hand side represents something that looks like EVMS because it contains Earned Value, but none of the discipline necessary to ensure the integrity and traceability of the EVMS data. Most people that talk about EVM Lite want to be closer to the left hand side of the continuum.

Any alternative approaches must consider the trade-off between the steps necessary to maintain good baseline control and system discipline versus implementation/ maintenance costs. If the performance measurement baseline is not adequately controlled, a good basis for measurement does not exist. If the earned value is not reliable and other data integrity issues exist, status reporting is suspect and the data cannot be used with confidence to forecast expected outcomes.

Humphreys & Associates can help a company’s team sort out which methods would work best for its project. H&A EVM experts can help determine which requirements can be relaxed, which ones need to be implemented and still maintain the fundamental EVM principles within each subsystem.

EVM Lite – Part 2: Tailoring approaches to EV Lite Read Post »