Why We Updated Our Most Popular Posts on Material Management in an EVMS Environment

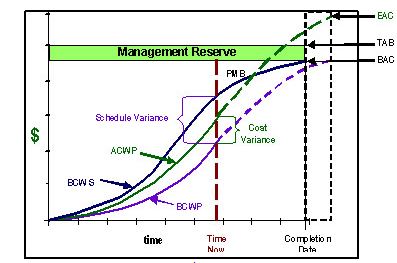

Earned value management of materials has many dimensions and can be challenging on development or production contracts. This includes planning, scheduling, budgeting, calculating earned value, properly aligning the actual cost of work performed (ACWP), and maintaining the estimate to complete (ETC)/estimate at completion (EAC) for performance reporting. A recent uptick in requests from contractors asking for help with resolving material management issues with their Earned Value Management System (EVMS) highlights this continues to be a major challenge.

For many government funded contracts, the material content represents a significant percentage of the entire contract. Any cost or schedule variances associated with material may dwarf the variances for labor and other direct costs along with the associated indirect costs. Corrective actions taken to address cost or schedule variances are commonly prioritized by their relative dollar value. The government customer will expect the contractor to pay attention to the highest-cost portion of the contract, underscoring the need for accurate and effective EVM for material.

We have updated and added content to our previous series of blogs on material management in an EVMS environment. These blogs address common issues our earned value consultants are observing on client engagements and focus on the basic requirements. The updated blogs include:

- Earning Value for Material – The Correct Approach – Part 1. This blog answers questions about the best points to claim earned value for the category of material.

- Earning Value for Material – The Correct Approach – Part 2. This blog discusses the different categories and classifications of material as well as acceptable earned value techniques to use.

- EVM Material Earned Value – Price vs. Usage Variance Analysis – Part 3. This blog discusses practical approaches for doing this analysis.

- Earned Value Management Systems (EVMS) – Residual Material Accountability – Part 4. This blog addresses material traceability and how to handle residual or excess materials purchased for a contract.

- Aligning ACWP with BCWP for Proper EVM | Earned Value Management. This blog discusses when it makes sense to use Estimated ACWP to ensure the material ACWP and budgeted cost for work performed (BCWP) are claimed in the same reporting period in the EVM cost tool.

- EVMS Compliance: Material Transfers and Loan/Paybacks. This blog provides an overview of material management and accounting system requirements and the difference between a material transfer and loan/payback to ensure project personnel know how to handle these situations.

Observations from Recent Engagements

- Enterprise systems and personnel’s ability to use those systems effectively.

For some contracts, the sheer volume of material acquired and managed by the contractor can be very large. A control account manager (CAM) might be responsible for many different part numbers, and dozens, hundreds or even thousands of individual parts. As the quantity of parts increases, the need for robust, highly automated and integrated enterprise systems used to manage material increases.

Company-wide commitment to business management systems that support the EIA-748 Standard for EVMS guideline requirements is critical. For some companies, implementation of the EVMS is not well understood or considered as their enterprise systems are selected and implemented, and they find that the systems do not support EVM well. This can become a significant and expensive problem. Attempting to support EVM using enterprise systems that are antiquated or not well integrated is difficult and may result in a need for inefficient manual data tracking activity that is expensive and prone to data entry errors.

Contractors that either already have, or anticipate winning, large government contracts are well-served to carefully examine their existing processes, research the available enterprise software systems, and conduct the appropriate training to ensure project personnel are equipped to support EVM.

CAMs with material elements of cost in their control accounts must be familiar with the enterprise systems that manage material, which differ from those used to track labor. Some examples of the enterprise tools that are critical for successful EVM of material include:

- The product data management tool that maintains the bills of materials.

- Systems that track material purchase order placement, material receipt, and supplier invoices.

- M/ERP system and the associated accounting reports used to track material demand, allocation, and residual material. This includes the grouping, pegging, and distribution (GPD) processes.

- Project integrated master schedules (IMS).

- The configuration management/change process.

- Quality reports (to track scrap and rework).

Key Points:

- Material EVM is critically important because of the high percentage of the contract value associated with material.

- Material EVM can be a complex process that requires a family of enterprise tools and processes within the company infrastructure. CAMs and other project personnel must understand and know how to use the output from those tools.

- Company-wide commitment to effective EVMS implementations that support the EIA-748 guideline requirements is extremely important to support successful EVM.

- EVMS process and procedures provide the necessary guidance to project teams.

Another challenge is ensuring the EVM System Description and related processes, procedures, and training materials provides the necessary guidance to project teams on how to implement the EVMS on contracts with significant material content. It is essential project personnel have clear, specific guidance and recurring training to ensure they are following a standard, repeatable process that support your enterprise systems and unique business environment.

Ensure the EVMS guidance addresses these topics:

- What is considered material, subcontract, or other direct cost (ODC) elements of cost.

- Material categories. This could be very simple for a non-production environment such as “receipt type material” and “inventory type material.” Material categories tend to be more specific for production environments and must be defined in alignment with the corporate enterprise systems. Applicable earned value methods or techniques to be used for a given category as well as BCWP and ACWP alignment is also a consideration.

- Material classifications. Material is typically classified as “high value,” “critical,” or “low value” materials. The material classifications as well as category are useful to state the applicable earned value technique to use. High value and critical materials must always use objective discrete earned value techniques.

- Material planning, performance measurement, and ACWP. Material requirements should be planned, scheduled, and budgeted to reflect a defined need date and how earned value will be claimed to ensure the budgeted cost for work scheduled (BCWS), BCWP, and ACWP can be consistently compared in the EVM cost tool for the same accounting/reporting period. Define the points for planning and claiming earned value as well as the accounting recognition points and how they are aligned for claiming earned value in the same accounting/reporting period for the various material categories.

- Approach for interfacing the IMS with the production schedules. Material processes affect the IMS such that the wrong methodology can increase the size and complexity of the IMS with little or no payback.

- Variance Analysis Reporting (VAR). A recurring request for H&A Earned Value training includes how to analyze the EVM metrics, perform a root cause analysis, and produce a useful VAR narrative. For control accounts with material elements of cost, the CAM should know how to perform a price versus usage variance analysis. The narrative should clearly describe the problem, the root cause, the scope of the impact to the control account or work effort, and recommended corrective action with sufficient backup information to substantiate the analysis.

The list of blogs at the beginning provide more information on most of these topics.

Key Points:

- Project personnel must know the difference between what is considered a material, subcontract, or ODC element of cost and how they are handled.

- Ensure your EVM System Description and related materials provide clear, specific guidance on how to plan, schedule, budget, claim BCWP, align ACWP, and maintain the ETC/EAC for the different categories and classifications of material.

- Conduct recurring training to ensure project personnel know how to use the applicable software tools to plan, schedule, budget, determine schedule status, claim earned value, use estimated actuals, and maintain their ETC/EAC for work effort that includes material elements of cost.

Need help?

Material management can be one of the most complex subsystems to incorporate into an EVMS. As the “911” for EVMS, H&A has worked with numerous contractors to sort through their unique material requirements and enterprise business systems to resolve their EVMS issues. Call us today at (714) 685-1730 to get started.

Why We Updated Our Most Popular Posts on Material Management in an EVMS Environment Read Post »