Level Of Effort Decision Tree – Clarifying Source Articles

Updated January 20, 2021

Level of Effort Decision Tree – Introduction

If you have not read the LOE source articles, Level of Effort (LOE) Replanning and How to Avoid Corrective Action Requests Related to Level of Effort, it is necessary to read prior to these articles in order to have the context for the following subject matter.

Humphreys & Associates, Inc. prepared an EVM consulting article a couple of months ago in order to increase the awareness of Earned Value Management Systems (EVMS) reviews related to Level of Effort (LOE) replanning. This resulted in considerable attention because we did not adequately explain our intention.

We had hoped readers would recognize that there are many strong and diametrically opposed opinions on acceptable approaches to LOE replanning. An important point to remember is that the principal purpose of an EVMS is to provide adequate information from which to make logical, well-informed decisions based on the best data available.

Our article resulted in a request for the National Defense Industrial Association (NDIA) Integrated Program Management Division (IPMD) to address this topic in its EVMS Clearinghouse Working Group. The company that submitted the issue used one of the approaches that we listed, which led to a DCMA Discrepancy Report. Consequently, they were clearly concerned. To address that one issue would not have provided an intelligent approach – it would have resulted in even more concerns for other organizations. For that reason, we chose to provide an update to our article in the form of a “white paper.” We do not address the many approaches being employed, as some display thinking that is “way out of the box;” such as earning whatever the actual costs are – as opposed to the budget.

We chose to leave some of those approaches out of the options addressed below. One could almost conclude that we are observing the classic consultant response to some issues – “It depends.”

BACKGROUND

The distinctive feature of the Level of Effort (LOE) earned value technique is that it earns value through the passage of time with no consideration of any work being performed. Therefore, it can earn value with no incurrence of actual costs and incur actual costs without earning value. Both of these conditions are currently considered by some DCMA review teams as noncompliant to the EVMS Guidelines (#16 and/or #22) that could result in a DCMA issued Corrective Action Request (CAR).

This is usually not an issue for the typical LOE that is support to the entire project (e.g., project management, contract management, financial management, systems engineering, security, safety, etc.) because these efforts almost always start on time and only face a problem if the support extends past the contract baseline. However, it is frequently an issue for LOE that provides support to discrete efforts that could slip or be moved up for various reasons (e.g., test site availability, equipment failures, successes that eliminate future planned effort, etc.) if the LOE work is not allowed to be replanned to the time period where the discrete work is actually being performed.

The LOE baseline period of performance should match the discrete effort’s period of performance. While the discrete effort can occur early or late and have earned value and actual costs coincide, that is not necessarily true for the supporting LOE, because it earns its value as planned in the baseline regardless of when the work actually starts or when the actual costs are incurred. The examples below show the possible LOE conditions when discrete effort starts early, finishes early, starts late, and finishes late. Each condition trips a significant item of concern when the DCMA runs its diagnostics of a contractor’s EVMS data:

If the discrete effort starts early, and LOE is not allowed to replan, LOE incurs ACWP with no BCWP.

If the discrete effort finishes early, the remaining months of LOE support earn BCWP with zero ACWP.

If the discrete effort starts late, LOE earns value (BCWP) with no actual costs (ACWP).

If the discrete effort finishes late, LOE incurs ACWP without accompanying BCWP because the BCWP now equals the BAC. However, when the support effort’s manager reports an EAC that includes the to-go LOE to report an accurate EAC, it creates the situation of EAC>ACWP with BCWP=BAC, again tripping a DCMA significant item of concern.

These conditions have resulted in Corrective Action Requests (CARs) from some local DCMA representatives because they are identified as significant items of concern by the DCMA diagnostics. Unfortunately, the diagnostics applied to discrete work packages are also applied to LOE tasks. There is no consideration of the special circumstances associated with LOE in the diagnostic software being used by review teams.

It is important to note that LOE is often (erroneously) called a work package just like discrete effort is called a work package and, therefore, work package rules are automatically applied to LOE. But not all work package attributes apply to LOE. For example, LOE does not consist of discrete tasks, is not required to be of short duration, and does not measure performance. The special circumstances of LOE were recognized in 1991 by the Department of Defense issuance of the Performance Measurement Joint Executive Group (PMJEG)’s Supplemental Guidance to the Joint Implementation Guide (JIG) involving the Cost/Schedule Control Systems Criteria (C/SCSC). Section 3-6, Revisions, subsection b (Internal Replanning) specified special handling of LOE for the circumstances cited above. However, the JIG Supplemental Guidance has not been incorporated into current implementation guidance. Please note that some DCMA EVMS Center of Excellence personnel have stated that the 1991 JIG Supplemental Guidance is applicable to current guidance. This is the way it used to be and was understood by all. But that position has not been documented and distributed to DCMA field office personnel, resulting in different determinations as to which actions are allowable and which are not. Many DCMA field office EVMS personnel have never been exposed to the JIG Supplemental Guidance. Those that are aware of the 1991 JIG Supplemental Guidance or who would agree with the JIG Supplemental Guidance approach as being compliant tend not to create CARs for the same conditions, while, unfortunately, those who are not aware of the Guidance write CARs.

INTRODUCTION TO THE DECISION TREE

The following decision tree relies heavily on the JIG Supplemental Guidance for recommending actions to avoid CARs. It is organized in outline format with major sections being the four discrete effort status possibilities that can cause LOE to result in a CAR as shown above. The first sub-topic in each section is the supporting LOE condition that results in tripping a significant item of concern in the diagnostic software DCMA employs from the Data Call before arriving on-site. The second sub-topic provides a quotation from the PMJEG Supplemental Guidance to the C/SCSC JIG, Section 3-6 Revisions, Subsection b. Internal Replanning that applies to the identified condition. The third sub-topic provides suggestions on how to implement the guidance to avoid the condition. The following sub-topics provide the advantages, disadvantages, and reporting requirements for each avoidance action.

In presenting these actions we need to make the point that depending on the interpreter none of these or only some of these would be acceptable to a DCMA reviewer. We are merely attempting to bring forth the options observed so that many can consider which approach is best for them and then use simple examples to present their desires to their customers.

Note that JIG references to “cost account” apply to control accounts.

LEVEL OF EFFORT (LOE) DECISION TREE

OUTLINE

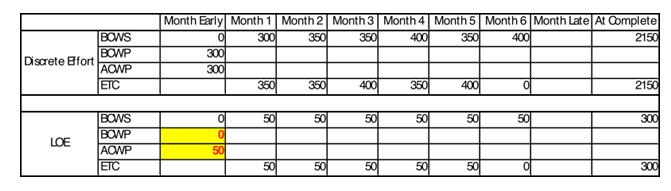

Discrete Effort Starts Early

- Condition that may result in a DCMA CAR

- The LOE BCWS does not start until a later period (cannot earn value in the current period).

- LOE has ACWP without BCWP, a significant item of concern condition.

- Applicable JIG Supplemental Guidance, Internal Replanning

- Paragraph (3)(c).

- “Replan future LOE to correlate to the changes in work. LOE, whether planned in separate cost accounts or as part of predominantly discrete cost accounts, has additional flexibility and may be adjusted within the current accounting period without government approval, provided no actual costs (ACWP) have been charged to the LOE.”

- How to implement the Supplemental Guidance

- In the current accounting period, replan the LOE to begin in the current period.

- Determine whether the discrete effort’s early start will result in an early finish (length of the period of performance remains the same).

- If so, no BAC change should occur – only the shift in the BCWS.

- If not, either provide additional BAC from MR or re-spread the BAC over the revised future period of performance (often called the “peanut butter” approach).

- Advantage

- Avoids the ACWP without BCWP condition.

- Disadvantage

- Changes the baseline in the current period. If the local DCMA office is not aware of the Supplemental Guidance or knows about its existence but disagrees with it, a CAR may be issued. Also, some DCMA teams consider the stretching out of current budget over a longer period of time as creating “token budgets” – for which they have written CARs.

- Reporting requirement

- Must be reported in Integrated Program Management Data and Analysis Report (IPMDAR) database for Format 5.

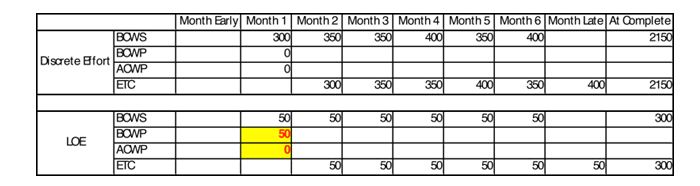

Discrete Effort Finishes Early

- Condition that may result in a DCMA CAR

- The discrete effort has finished early and if the LOE had not previously been replanned in anticipation of the early finish, no LOE support effort would be required for the remaining period(s) of the LOE BCWS that must still earn value.

- The LOE has BCWP without ACWP, a significant item of concern condition.

- Applicable JIG Supplemental Guidance, Internal Replanning

- Paragraph (3)(b).

- “Replan incomplete future work and adjust the work package budget at completion (BAC) to reflect the change in accordance with normal replanning guidance…”

- How to implement the Supplemental Guidance

- Because the “incomplete future work” has been eliminated, close the LOE package. The BCWS will already be equal to the BCWP earned to date.

- Subtract the BCWP from the BAC and return the BCWR initially to the UB Log and subsequently to the MR Log.

- If this can be achieved in the period in which the discrete effort was completed, this is a change to the next accounting period, thus avoiding a change to the current period baseline.

NOTE: There is another point to be made here. The LOE task was to support the discrete work scope no matter how long it took. If the discrete task finished early because its work scope was reduced, the LOE task requirement was also reduced and the above action is justified. If the discrete task simply finished early, this would be a cost variance in that it cost less to support the unchanged work scope. The above action would be done solely to avoid the BCWP without ACWP condition.

- Advantage

- Avoids the BCWP without ACWP condition.

- Disadvantage

- If the change is made in the same period in which the discrete effort was completed (or a prior period), there is no disadvantage although some would argue that this approach would be “changing budgets based on performance” which is akin to using MR to hide true cost variances.

- If the change is made in the period subsequent to the completion of the discrete effort, the current period baseline will change. If this is a repetitive occurrence, it probably means that a contractor is constantly changing the baseline to avoid true cost variances; therefore, it may result in a DCMA CAR.

- Reporting requirement

- Must be reported in IPMDAR database for Format 5 (MR was increased).

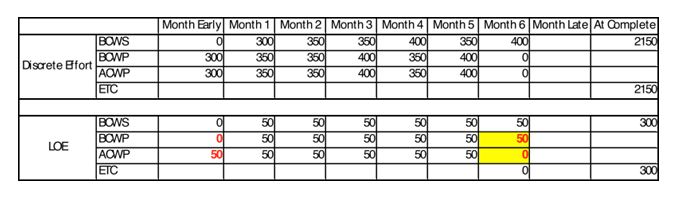

Discrete Effort Starts Late

- Condition that may result in a DCMA CAR

- The discrete effort has not started (no ACWP or BCWP), hence no LOE was required. This results in zero ACWP for the LOE, but it does report BCWP because of the passage of time.

- The LOE has BCWP without ACWP, a significant item of concern condition.

- Applicable JIG Supplemental Guidance, Internal Replanning

- Paragraph (3)(c).

- “Replan future LOE to correlate to the changes in work. LOE, whether planned in separate cost accounts or as part of predominantly discrete cost accounts, has additional flexibility and may be adjusted within the current accounting period without government approval, provided no actual costs (ACWP) have been charged to the LOE.”

- How to implement the Supplemental Guidance

- In the current month replan the LOE to begin in the month that the discrete effort is currently scheduled to begin.

- Advantage

- Avoids the BCWP without ACWP condition.

- Disadvantages

- Changes the baseline in the current period. If the local DCMA office is not aware of the Supplemental Guidance or disagrees with the Supplemental Guidance, a CAR may be issued.

- If the discrete effort recovers its schedule variance, the LOE will be put in the position of having BCWP yet to be earned with no LOE required (equivalent to the early finish condition presented below).

- Reporting requirement

- Must be reported in IPMDAR database for Format 5.

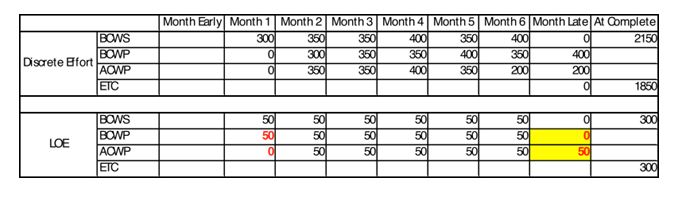

Discrete Effort Finishes Late

- Conditions that may result in a DCMA CAR

- The LOE incurs ACWP with no accompanying BCWP.

- The LOE incurs ACWP with no accompanying ETC, usually indicated by ACWP>EAC.

- Both of these are significant items of concern conditions.

- Applicable JIG Supplemental Guidance, Internal Replanning

- Paragraph (3)(b).

- “Replan incomplete future work and adjust the work package budget at completion (BAC) to reflect the change in accordance with normal replanning guidance…”

- How to implement the Supplemental Guidance

- In or before the last period of performance of the LOE, replan the LOE to cover the extended discrete effort.

- Use one of two methods to provide budget for the additional effort:

- If ACWP is less than BCWP, recover budget from the previously earned LOE BCWP by using the single point adjustment technique of setting BCWS and BCWP equal to ACWP and replan the recovered budget (BAC minus BCWP) into the future.

- If ACWP is equal to or greater than BCWP, but less than BAC, replan the unearned budget (BAC minus BCWP) into the future.

NOTE: Alternative to 3) implementing the Supplemental Guidance

- Allow the LOE package to complete without replanning, which results in accepting the ACWP without BCWP condition.

- To mitigate the severity of this approach, be certain to provide an ETC for the periods beyond the LOE baseline period of performance. This action would avoid an ACWP>EAC condition.

- Advantages

- Avoids the ACWP without BCWP condition.

- Avoids the ACWP>EAC condition.

- Disadvantage

- There will be a baseline change in the current period. Because ACWP has occurred, the LOE exception to be able to make a change in the current period if no ACWP has been recorded does not apply. Therefore, a DCMA CAR may be issued.

- Reporting requirement

- Must be reported in IPMDAR database for Format 5.

Observations/RECOMMENDATIONS based on the foregoing:

- First and foremost, because many DCMA personnel are not familiar with the JIG Supplemental Guidance or may not agree with it (remember that the DCMA Center of Excellence has not formally confirmed that the JIG Supplemental Guidance remains in effect), contractors must determine the desired approach of the cognizant DCMA personnel for handling the LOE conditions noted above. Early discussions to determine acceptable approaches to the LOE special conditions will avoid many of the CARs/DRs being issued.

- Eternal vigilance is required. If a potential change in the performance period of the discrete effort becomes apparent sufficiently early, the change can be accomplished with little chance of incurring a DCMA CAR. This assumes that people recognize the right to change LOE in an “open LOE task”.

- The DCMA Center of Excellence must officially transmit additional guidance to the DCMA field offices to ensure consistent application of EVMS Guideline requirements to LOE.

- Some may suggest using the Apportioned Effort technique in lieu of LOE, but that would require that the supporting budget be estimated as a percentage of the discrete effort and its time-phasing be established at the same percentage as the time-phasing of the base. Usually, LOE budget is based on an average level of support that is inconsistent with or has a “loose” relation to the discrete package’s time-phasing.

- One alternative approach is to consider short duration (3-4 months) LOE for supporting discrete effort. An advantage to this approach is that while the first LOE in the series might incur a significant item of concern condition, the following efforts could be adjusted without penalty.

- Another alternative approach is to make the entire support effort a percent complete EVT work package with the Quantifiable Backup Data (QBD) being the milestones in the supported discrete effort.

- If the LOE has been reported as complete in the prior month, it has been suggested by some in the DCMA EVMS Center of Excellence that the LOE BCWP that has already been earned can be “harvested” to budget a continuation of the LOE past its original period of performance. This was not a consideration of the JIG Supplemental Guidance and most would argue that this approach is in direct conflict with Guideline 30. Contractors should not use this method unless it is formally approved by the DCMA EVMS Center of Excellence.

To contact Humphreys & Associates click here.

Level Of Effort Decision Tree – Clarifying Source Articles Read Post »