Along the IMS Time-Now Line

Recently one of our consultants was instructing a session on the Integrated Master Schedule (IMS) with a group of project personnel from one of our larger clients. The group was a mixture of beginners with no real experience in schedules and some much more experienced practitioners; some with more than 10 years of experience. The mixture made it somewhat difficult, but it also made for some interesting discussions that might have been missed in a more homogenous group. One of those things was the usefulness or importance of the “time-now” line.

Recently one of our consultants was instructing a session on the Integrated Master Schedule (IMS) with a group of project personnel from one of our larger clients. The group was a mixture of beginners with no real experience in schedules and some much more experienced practitioners; some with more than 10 years of experience. The mixture made it somewhat difficult, but it also made for some interesting discussions that might have been missed in a more homogenous group. One of those things was the usefulness or importance of the “time-now” line.

When the group was asked about the importance of the time-now line and what information could be easily gained from a look at the line, there was silence. The beginners did not have a clue but also none of the experienced people had any response. What should have been a short discussion with just one “slide” as a visual, turned out to be a longer and more informative session on this topic.

The time-now line has different names in different software tools but it refers to the data date, or status date, of the schedule. That also would be the first day of the remainder of the schedule. When a scheduler sorts tasks by date, the time-now line runs down the screen and forms a highly useful visible reference.

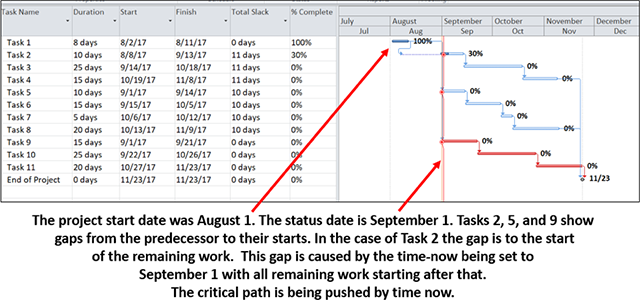

In the small example below [see Figure 1], you can see the time-now line and visually assess the situation. Time-now is shown by a vertical line at the beginning of September, so all remaining effort has been scheduled to after that date. In other words, no work can be forecasted in the past. A walk down the line shows Task 1 has both started and completed. Task 2 started but has not completed. In fact, the remaining work in Task 2 has been pushed out by the time-now line. The start of Tasks 5 and 9 are also being pushed out by the time-now line. In most real project schedules, filters and other techniques may be needed to isolate information like this; but in our small example, we can simply “eyeball” the time-now line and see valuable information. Task 9 starts the critical path shown in red tasks.

Figure 1

Figure 1

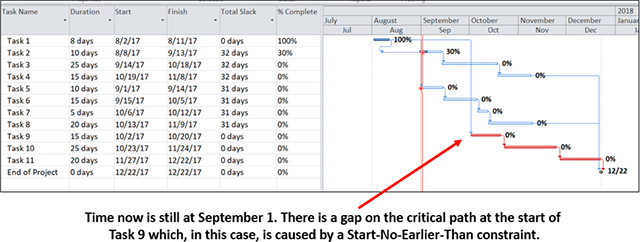

A slightly different setup for that same small example [see Figure 2] shows something interesting. The time-now line is still at the beginning of September. But now there is a gap between time-now and work on the critical path. This is an unusual situation and should be investigated for the root cause. It is possible this is an accurate portrayal of the situation, but regardless of the cause, it must be verified and explained.

Figure 2

Figure 2

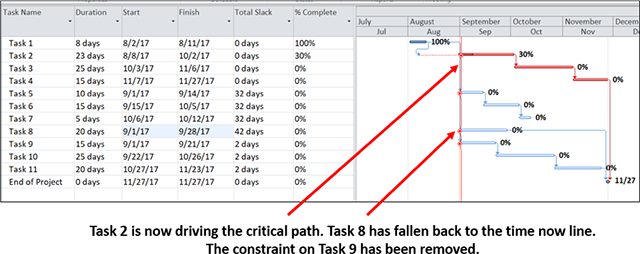

In yet one more variation [see Figure 3], we see that a broken link results in Task 8 ending up on the time-now line. A task without a predecessor will be rescheduled to start at the earliest possible time (if the task is set to be “As Soon As Possible”). And the earliest possible time is the time-now line; the beginning of September. Just as broken things fall to the floor in real life, “broken things” fall to the time-now line in a schedule. Un-started work can land there. Un-finished work can land there. And un-linked work can land there.

It is further possible to see that Task 2 has had an increase in the remaining duration that has driven it onto the critical path. Task 2 at this moment is the most important task on the entire project. A slip to Task 2 will drive out the end date for the entire project. One question that needs answering is what is holding up Task 2?

If the display had been sorted by increasing total float/slack and the usual cascade by date, then the critical path would be starting at the upper left-hand corner; like the critical path in this example. The action on the project is almost always on the time-now line and the most important action, when sorted as described, will be at the upper left-hand corner.

Figure 3

Figure 3

So, a walk down the time-now line can help us see the critical path action, find broken parts of the schedule, and locate unusual circumstances that need our attention. Our recommendation is to look at the time-now line any time there is data being changed in the IMS. This will help you catch issues early and keep the schedule cleaner.

Along the IMS Time-Now Line Read Post »